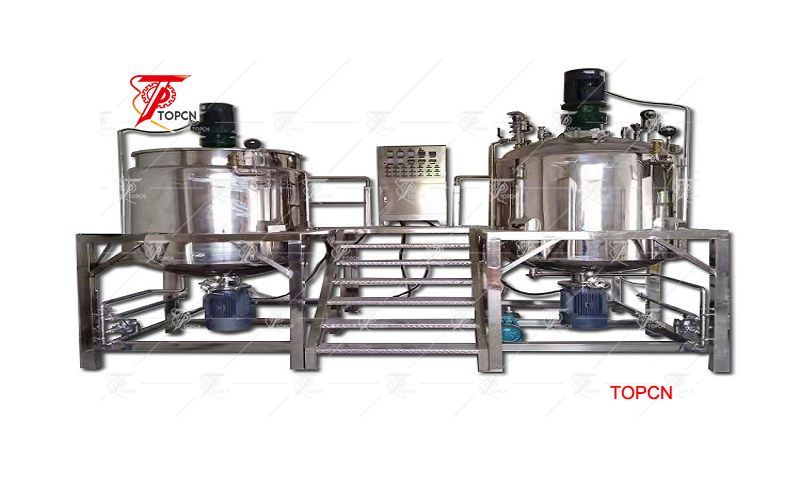

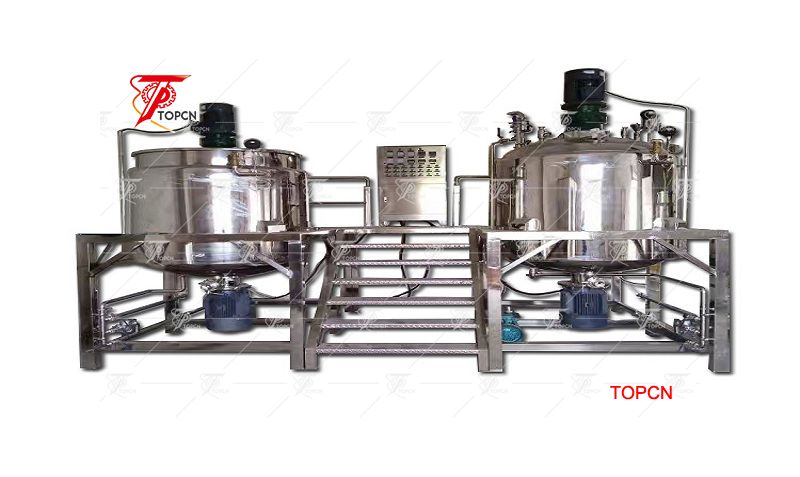

1000L electronic heating shampoo oil hair gel mixer machine group

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

1000L electronic heating shampoo oil hair gel mixer machine group is designed specially for cosmetic and pharmaceutical industries to produce and deal big batches of different varieties of products.

►Mixing use triple blender, which is the design that have positive and negative turn of matching a high speed Sharing head and a slow stirring vane.

► Advanced disperser with unique structure and reliable sealing (the mechanical seal adopt Germany Bergman product), and the Disperser rotation speed of 0-3600 rpm (Panasonic frequency conversion).

►Made of imported SUS304 or SUS316L stainless steel. The shampoo mixer tank body and pipe are carried out mirror polishing, which is in complete accordance with GMP standard.

►The vacuum defoaming can make the materials meet the requirement of being sanitary and aseptic. The vacuum sucking material adopted can avoid dust, especially for the powder products.

► According to technological requirements, the tank can heat and cool the material. The heating method can be chose to steam or electric heating according to customer requirements

2 Ton vacuum shampoo oil hair gel mixer machine

The tank can be add a jacket for cooling or heating .

The tank electric heating or steam heating.

pot capacity | working capacity:1000L *2 |

Material | Contact with material:SUS316 |

Outer layer: SUS304 thickness:3mm | |

Inner layer: SUS304 thickness:10mm | |

Middle Layer SUS304 thickness 8mm | |

Homogenize | bottom homogenizeX2 |

Homogenize motor power:7.5 kwX2 | |

Motor speed:300~3040RPM | |

Mixing way | Frame type two-way mixer with scraper(TEFLON scraper) |

Mixing power:4kwX2 | |

Mixing speed:0-83 rpm | |

Hating type | Steam heating or electric Heating, Tap water cooling |

Heater | 9KW*4 |

Opening way | Open cover (two tank) |

Temperature display | resistance thermometer |

Out of the material tank bottom valve discharge (2 inches) | |

Spare parts | 1 year warranty |

Warranty period | 1 year |

Working life | 10 years above |

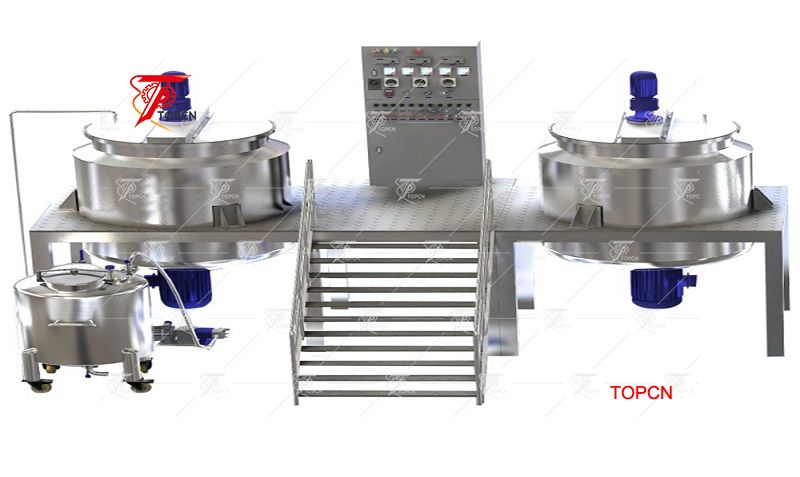

Automatic Shampoo oil hair gel mixer and washing liquid production line equipment Mixer

shampoo mixer machine group with pump and storage tank , finish products is transfered to the storage tank by the pump.

1. DELIVERY LEAD TIME:

30-50WORKING DAYS AFTER RECEIVED DEPOSIT.

2. TERMS OF PAYMENT:

BY 30% IN ANVANCED, THE BALANCE 70% BY T/T BEFORE SHIPMENT.

3. PRICE VALID UNTIL:

15-20DAYS.

4. PACKING:

WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT.

5. PORT OF SHIPMENT:

GUANGZHOU or SHENZHEN PORT.

For your inquiries, pls kindly let us know:

1. What is your products?

2. What is the capacity do you want for this vacuum emulsifying machine? 100L, 200L300L, 500L, 1000L, etc.

3. Required heating method: electric heating or steam heating?

4. Required voltage and frequency of power supply? eg: 380V 50Hz 3phase?

5. Requirement of Certificate (CE, UL, CSA, or no need)

Q1: Are you a machine manufacturer or trading company?

A1: We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's requirement. Welcome to visit our factory!

Q2: How do you guarantee this machine normally operating?

A2: Every machine is tested by our factory and other client before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in warranty year.

Q3: How can I install this machine when it arrives?

A3: We will send the engineers overseas to help client installing, commissioning and training.

Q4: Could I choose the language on touch screen?

A4: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, Japanese and etc,.

Q5: If I need oil and water tank, would you provide for me? How much it cost?

A5: Yes, we could provide oil and water tank for you. The price of oil and water tank depends on the volume of tank.

Q6: Can this mixer programme with flow meter and pumps to realize auto material loading?

A6: Yes, we can offer you Siemens PLC and touch screen to programme auto material loading.

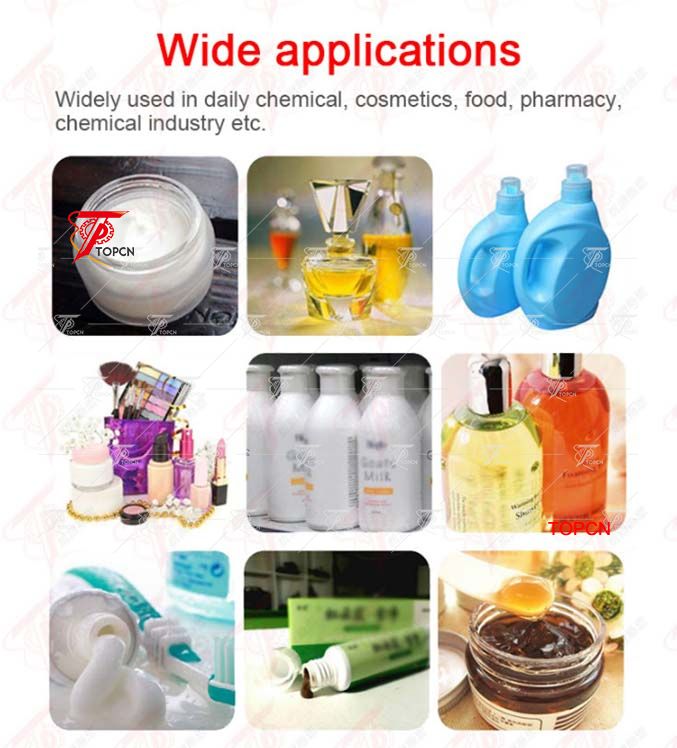

Q7: What kind of product can this machine make?

A7: Emulsifying machine is widely used in producing cream, sauce, wax, shampoo, and etc for food, cosmetic, chemical industry.

Q8: Do you have manual or operation video for us to know more about the machine?

A8: Yes,we will send you the manual and operation video after you ask for us.

Q9: If there's some spare parts that broke,how to solve the problem?

A9: Yes,we will send you the manual and operation video after you ask for us.

Q10: If there's some spare parts that broke,how to solve the problem?

A10: First of all,please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.

- Stainless Steel Tank

- Open Top 200L Perfume Mixer Machines Pneumatic Mixer

- 500 Liter Stainless Steel Cosmetic High Shear Mixing Tank Price With Circulating Pump

- Top Open 500L Homogeneous Liquid Soap Making Mixing Machine with Heating And Mixing Plateform

- Top Close 100L Essential Oil Perfume Tank Pneumatic Type

- 200L 100L Small Capacity Stainless Steel Liquid Soap Mixing Tank with Agitator

- Price of 500L paint mixing tank industry