Here is Liquid Filling Machine Manufacturer talking about What are the types of thread detection methods.

With the rapid development of the liquid food industry, the filling technology of liquid food has also developed rapidly. Liquid food filling technology mainly classifies hot filling technology and aseptic cold filling technology.

1. Hot filling technology

The hot filling technology refers to a filling technology in which liquid food is sterilized in a hot state and the inner surface of the container is sterilized by using the heat of the product. The hot filling can be divided into two types, one is high-temperature hot filling, one is medium temperature filling and then the product is heated to 65 ° C ~ 75 ° C for pasteurization. Hot filling technology eliminates the need to sterilize bottles and lids individually, allowing the bottles and lids to be sterilized by holding the product at high temperatures for a sufficient period of time.

2. Aseptic cold filling technology

Aseptic cold filling technology refers to the cold (normal temperature) filling of the product under aseptic conditions. The key control points for aseptic cold filling technology are mainly concentrated in the following three points: the formation and control of the aseptic environment, the aseptic formation, and control of the packaging container, and the aseptic formation and control of the product. In order to meet the requirements of aseptic cold filling, the production line must meet the following basic requirements: the product is subjected to ultra-high temperature instantaneous sterilization to achieve commercial sterility, packaging materials and sealed containers are separately sterilized to achieve sterility, and the filling equipment is sterilized to achieve sterility. The state, filling, and capping are carried out in a sterile environment, the production process is strictly controlled and each critical control point is established, monitored, recorded and controlled.

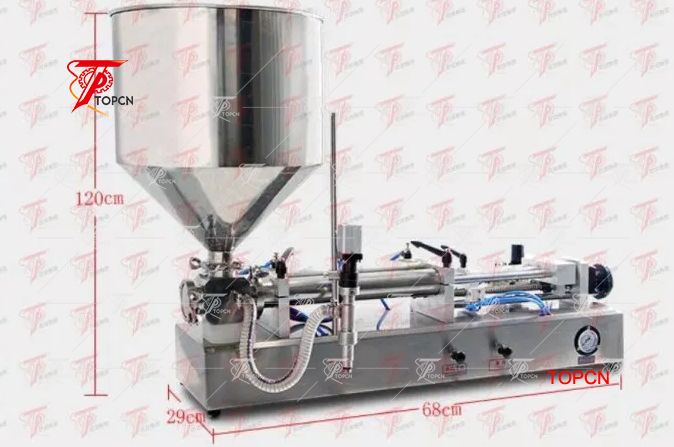

For more information about Semi Automatic Filling Machine For Chemical, please contact or call us.