Three Roller Mill

- Application

- Description

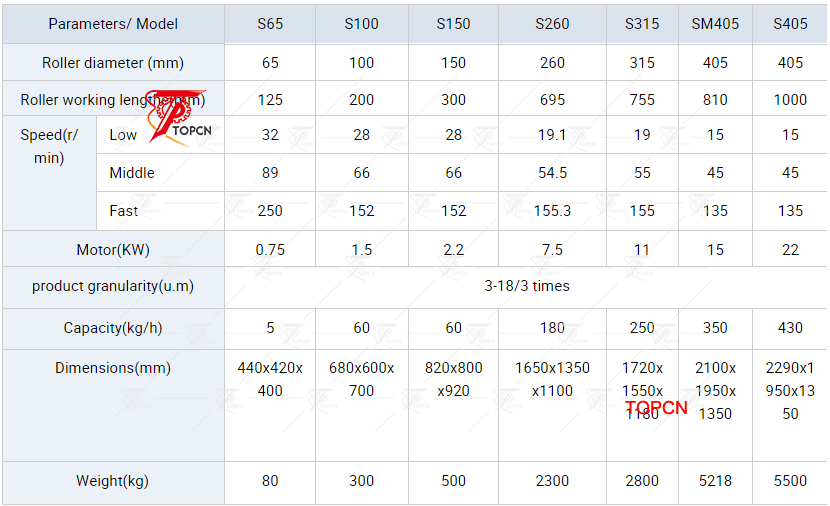

- Products Parameters

- Video

- Package&Shipping

- FAQ

Triple Roller Mill is ideal grinding and dispersing equipment to process high viscosity material.It can be mainly used in Oil Paint, Printing-ink, Color Paste, Plastic Paste, Cosmetic, Soap, Ceramics,Rubber.

· The welding type structure is adopted by the frame.The highly hard and cold molded alloy roll cylinder is driven and rotated by motor.

· The cylinder,gearing wheel and belt pulley are adjusted by dynamic balance so it operates with the lowest noise.The advanced double cylinder designed for hydraulic system and the key hydraulic parts are chosen from Parker(imported).So the mill has the advantages that it is highly sensitive in movement and its hydraulic is greatly reliable.

· When the cooling water stops or temperature of the cylinder is too high or the current overloads or something drops into the cylinders,the mill wilt stop automatically.

· The highly sensitive super-sonic sensor can watch the material's surface and the system will stop working when the quantity of the material is below the level of material surface designed.ln this way, the safety of equipment can be guaranteed.

· The three-roll mill is able to match feeder,bead mill,etc.to be the efficient and continuous processing unit.

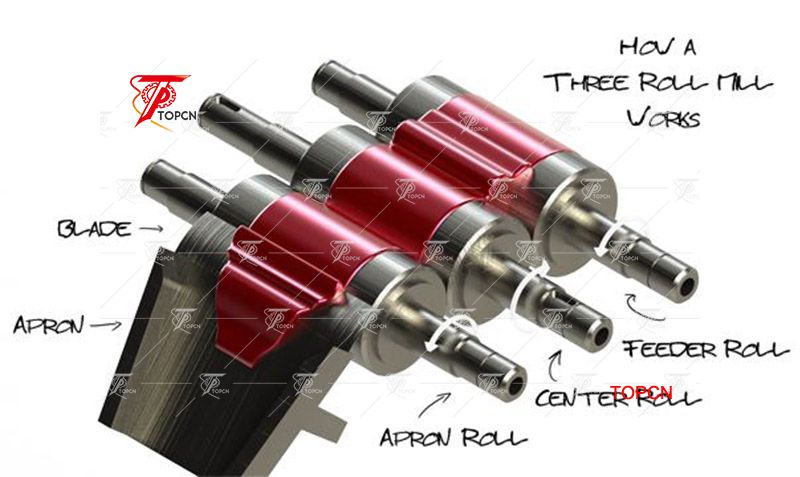

· The three-roll mill' s working principle

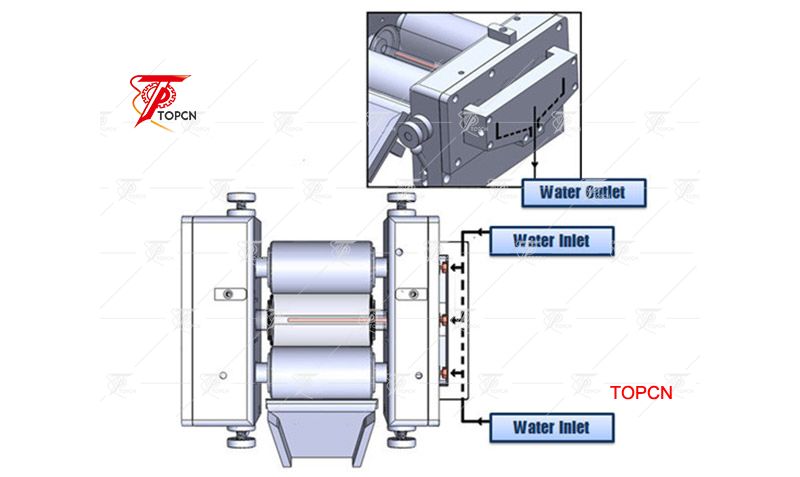

· Each cylinder is matched with independent cooling system,which is accurately controlled.The working temperature required by the material can be set and kept evenly and steadily.

· There are three operation positions for the three rolls of the three roils:

a. Separated each other for cleaning

b. Two rolls are clamped,the third one is separated for mixing the material.

c. Three rolls are clamped for dispersing and discharging of material.

| Name | Qty | Technology parameter |

| Model: 70 mixer | 1 | Mixing various raw materials for producing soap and transparent |

| soap thoroughly and evenly, to refine neat soap, and completely | ||

| mix various auxiliary materials and additives and flavors into neat | ||

| soap to reach the recipe requirements. | ||

| Capacity:70kg/batch | ||

| Soap Fined machine | 1 | Capacity:1000kg/h |

| Motor:15Kw | ||

| Size:2600*1200*1700 | ||

| Weight:1100Kw | ||

| S260 three roller mill | 1 | Roller diameter:260mm |

| Working face length:695mm | ||

| Power:7.5kw | ||

| Dimension:1650*1350*1100mm | ||

| Weight:2300kg | ||

| C245double vacuum plodder machine | 1 | Capacity:500-800kg/h |

| Powder:7.5kw/15kw | ||

| Dimensions:4000*1000*2450mm | ||

| Weight:2570kg | ||

| Soap printer | 1 | Capacity:60-120pcs/min |

| Power:2.2Kw | ||

| Weight:1000kg | ||

| Dimension:1450*800*1100mm |

1. DELIVERY LEAD TIME:

35-50 WORKING DAYS FOR THE SEMI AUTOMATIC MACHINE AFTER RECEIVED DEPOSIT

2. TERMS OF PAYMENT

BY 40% IN ANVANCED, THE BALANCE 60% BY T/T BEFORE SHIPMENT

3. PRICE VALID UNTIL

30 DAYS.

4. PACKING:WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT

5. PORT OF SHIPMENT

GUANGZHOU or SHENZHEN PORT

1, Q: Soap industry production process?

A: Basically, the soap production need 2steps:

a, using all kinds of oil&fast as material to produce semi-finished soap noodle;

b, using seme-product soap noodle to produce end bar soap.

2, Q: What are the kinds of the soaps?

A: For convenience, we separate the soap into two kinds, toilet soap for washing hand&taking bath, herbal soap, hotel soap, antiseptic soap are included;

The second kind is laundry soap for washing clothes, etc.

3, Q: What kind of oil is suitable for soap production?

A: All kinds of vegetable oil and animal fats are usable, palm oil, cottonseed oil, tallow oil, coconut oil, sunflower oil, etc.

4, Q: What is the floor of the workshop size?

A: For oil line: 35*7m with height 7m;

For soap noodle line: 25*3m with height 4m.

5, Q: What is the formula?

A: Raw material is oil, caustic soda and salt; semi-product is soap noodle, perfume, and color.

Accurate formula based on your local market's request is available after confirmation of order.

6, Q: How about the Engineer and technique support?

A: 1, We would send engineer overseas for machine installation, staff training, and production test running, till your own staff can operate the machine well and product out qualified soaps.

2, During the lifespan of our machines, we should give consistent technique support and service, and we are the pleasure to be in service of you.(24hours online)