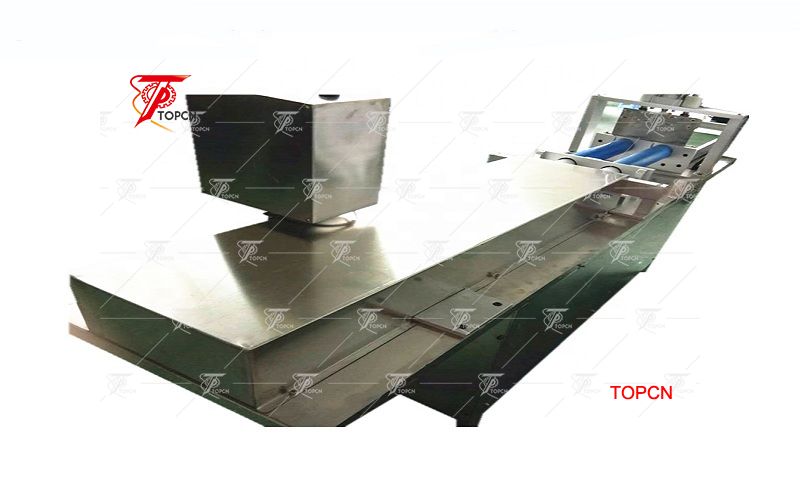

pipe cooling soap pushing and cutting machine round pipe moulding soap cutter machine

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

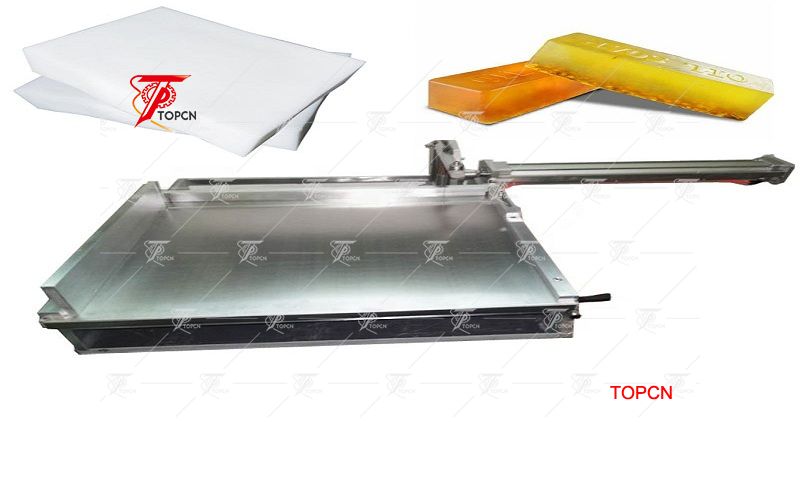

pipe cooling soap pushing and cutting machine round pipe moulding soap cutter machine is the special designed for cutting soap (soap formed in the pipe mould, cube pipe, round pipe, or other shape pipe are all ok.

Machine operation:

1. Pouring the soap liquid into the pipe, after cooling, the soap pipe can be place onto the machine directly, and then start the machine, the machine will push the soap from the pipe directly, and cut into the same thickness soap.

2. The cutting thickness can be adjusted to 0.01mm by the PLC control system.

Machine features:

1.This machine can be applied to variety soap cutting, soap weight can be adjusted according to the soap size, cutting speed by PCL control system.

2.The parameter can be set by the touch screen directly, which is convenient to adjust the cutting thickness.

3.Cutting size exact with the error ≤±2g

Machine model | TSCM-03C |

Working speed | 35seconds per pipe or 1 minute per pipe |

Power | 100w |

Machine voltage | 220v 50hz single phase |

Size | 2200*430*1200mm |

Machine weight | 135kg |

1. DELIVERY LEAD TIME:

5-7 WORKING DAYS AFTER RECEIVED DEPOSIT.

2. TERMS OF PAYMENT:

BY 30% IN ANVANCED, THE BALANCE 70% BY T/T BEFORE SHIPMENT.

3. PRICE VALID UNTIL:

15-20DAYS.

4. PACKING:

WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT.

5. PORT OF SHIPMENT:

GUANGZHOU or SHENZHEN PORT.

1, Q: Soap industry production process?

A: Basically, the soap production need 2steps:

a, using all kinds of oil&fast as material to produce semi-finished soap noodle;

b, using seme-product soap noodle to produce end bar soap.

2, Q:What is the kinds of the soaps?

A: For convenience, we separate the soap into two kinds, toilet soap for washing hand&taking bath, herbal soap, hotel soap, antiseptic soap are included;

The second kind is laundry soap for washing clothes, etc.

3, Q: What kind of oil is suitable for soap production?

A: All kinds of vegetable oil and animal fats are usable, palm oil, cotton seed oil, tallow oil, coconut oil, sunflower oil, etc.

4, Q: What is the floor of the workshop size?

A: For oil line: 35*7m with height 7m;

For soap noodle line: 25*3m with height 4m.

5, Q: What is the formula?

A: Raw material is oil, caustic soda and salt; semi-product is soap noodle, perfume and color.

Accurate formula based on your local market's request is available after confirmation of order.

6, Q: How about the Engineer and technique support?

A: 1, We would send engineer overseas for machine installation, staff training and production test running, till your own staff can operate the machine well and product out qualified soaps.

2, During the life-span of our machines, we should give consistent technique support and service, and we are pleasure to be on service of you.(24hours on line)

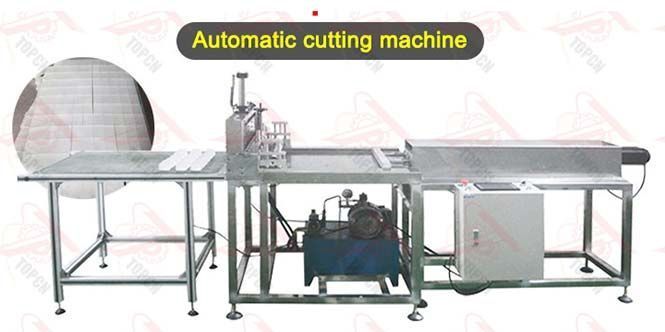

- Automatic Electric Cutting Machine Soap Cutters

- Big Block Soap Cutting Machine Soap Cutter Machine Price

- Square Tube Forming Soap Cutting Machine Long Strip Soap Slicing Machine Soap Cutter Price

- TPSC-04 Manual wire soap bar cutter China

- Manual Cylindrical Soap Strip Cutting Machine Small Soaps Slicing Machine without Table