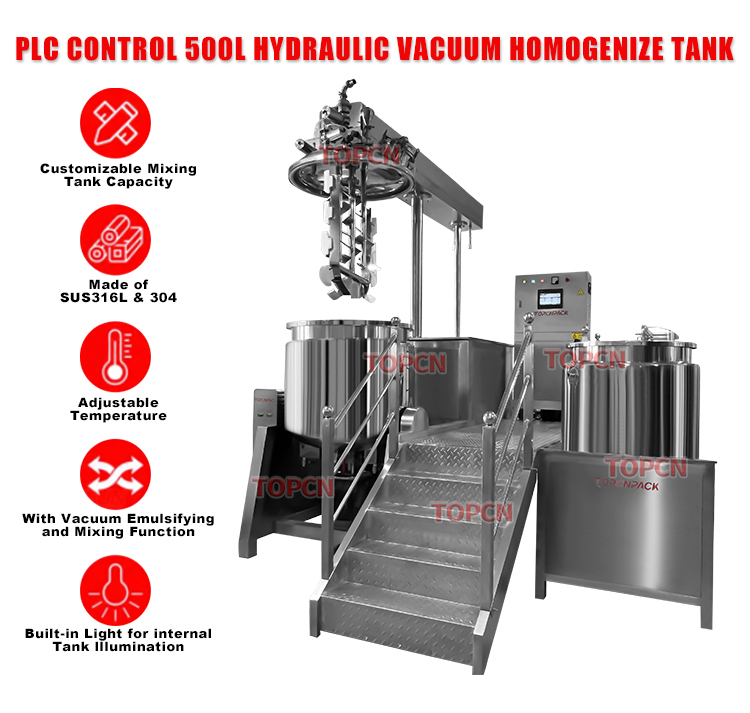

Cosmetic Production Line 100L Vacuum Homogenizer Mixer Machine Cream Making Machine Lotion Production Equipment

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

The product of vacuum emulsifying mixer machine mainly applied in such industries as daily chemical care products, food industry, paint and ink ,nanometre materials, petrochemical Industry, printing and dyeing auxiliaries, pulp & paper, pesticide, fertilizer, plastic & rubber, electronic and electronics, fine chemical industry, etc.

The emulsifying effect is more prominent for materials of high base viscosity and high solid content.

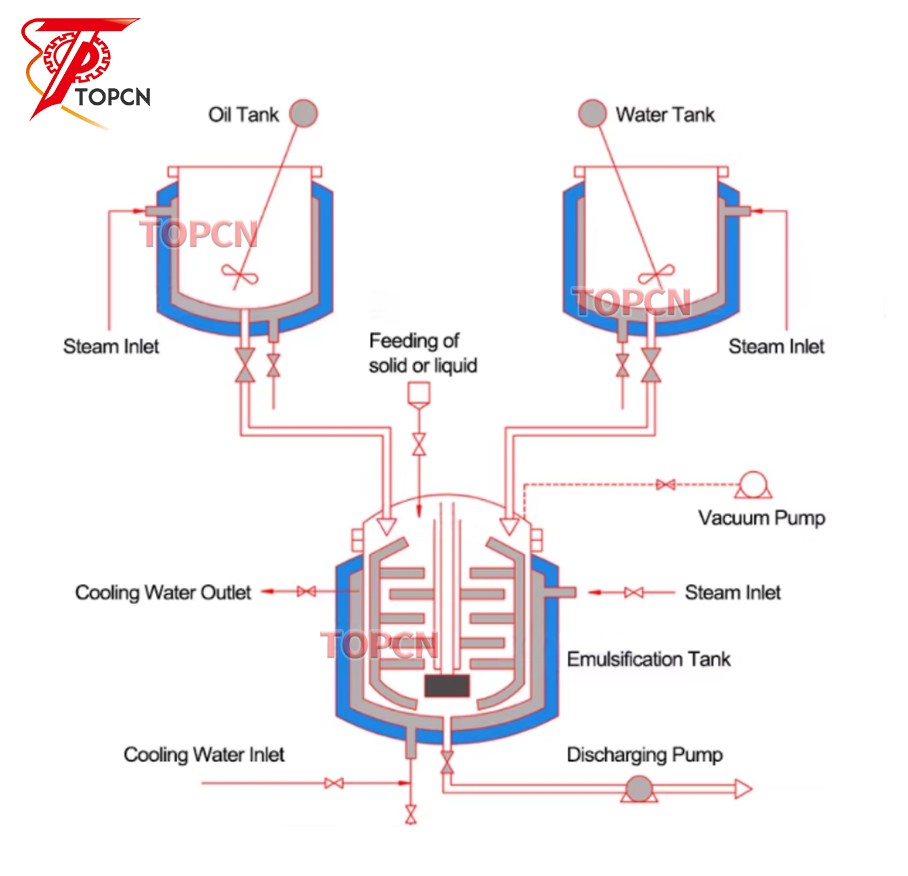

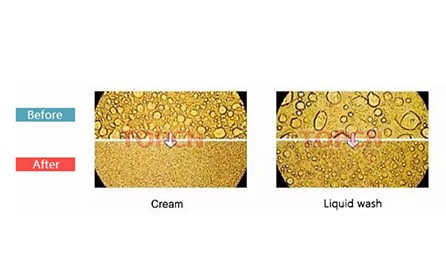

Vacuum Mixer Homogenize means when the materials are under the vacuum condition, it makes use of the high shear emulsifier to distribute one or several to another continuous phase rapidly and evenly. The materials will be processed in the narrow space between stater and rotor by strong energy of motion produced by the machine effect.

By the operation of hydraulic shearing, centrifugal extruding, impacting, breaking and turbulence for over 199 thousand times per minute, the materials will be dispersed and emulsified instantly and evenly. After reciprocating circulation at high frequency, the fine finished products of stable and high quality without bubbles will be achieved.

capacity (L) | Agitator power (kw) | Speed (rpm) | Homogenizer power (kw) | Speed (rpm) | Oil/Water tank (L) | Agitator power (kw) | Speed (rpm) | Hydraulic (KW) |

50 | 1.5 | 0~75 | 2 | 0~3600 | 20/45 | 0.37/0.37 | 0~1440 | 0.75kw |

100 | 2.2 | 0~75 | 3 | 0~3600 | 40/90 | 0.55/0.55 | 0~1440 | 0.75kw |

200 | 3 | 0~75 | 5.5 | 0~3600 | 80/180 | 0.75/0.75 | 0~1440 | 1.1kw |

300 | 4 | 0~75 | 5.5 | 0~3600 | 120/270 | 1.1/1.1 | 0~1440 | 1.5kw |

500 | 4 | 0~75 | 7.5 | 0~3600 | 200/450 | 1.5/1.5 | 0~1440 | 1.5kw |

1000 | 5.5 | 0~75 | 11 | 0~3600 | 400/900 | 2.2/2.2 | 0~1440 | 2.2kw |

2000 | 7.5 | 0~75 | 15 | 0~3600 | 800/1800 | 2.2/2.2 | 0~1440 | - |

3000 | 11 | 0~75 | 18.5 | 0~3600 | 1200/2700 | 3/3 | 0~1440 | - |

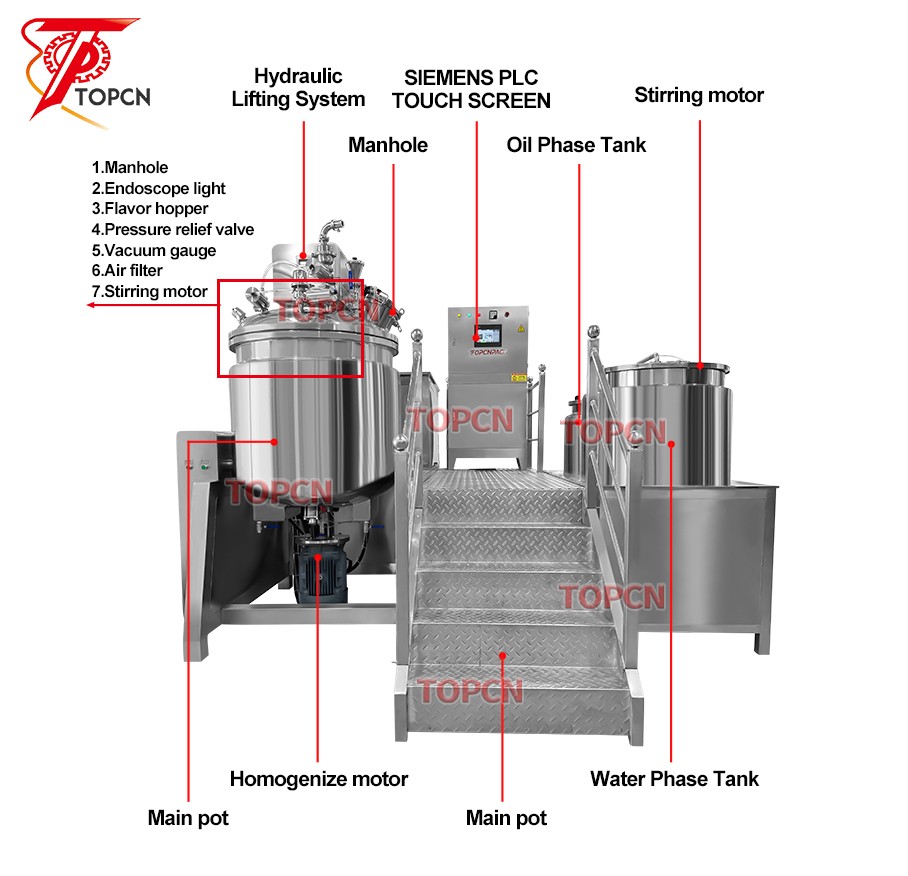

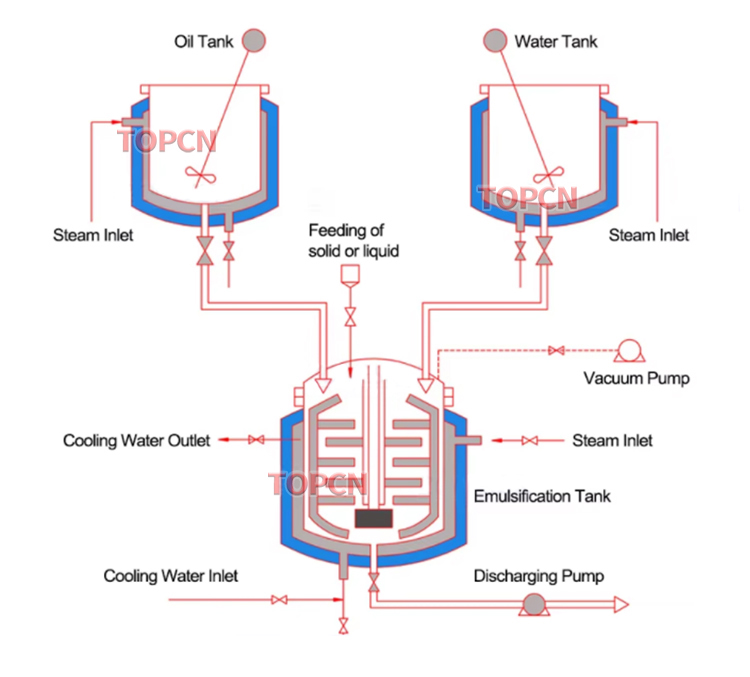

Automatic valve

And according to the preset parameters, the pneumatic valves are automatically opened or closed to replenish the required raw materials or adjust the medium pressure, ensuring that the emulsification process is always in the best condition.

Vacuum Pumps

Under the vacuum environment, theemulsification pot can discharge foamwhen the materials are mixed, thusimproving the quality of the materials tobe treated. Vacuum deaeration processcan ensure the sterility of materials

Accessories

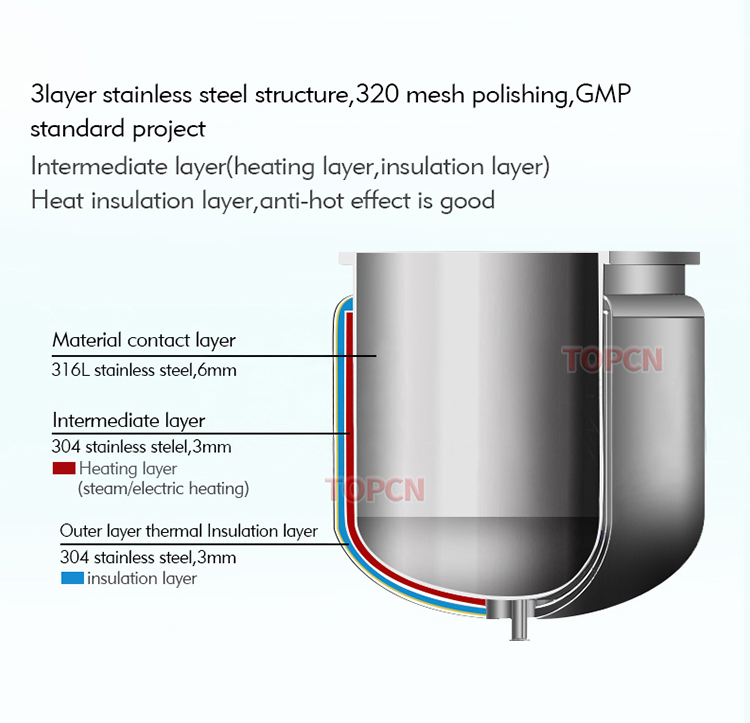

Material SS316, thickness 6 mm,Equipped with suction filter, drain valve,.vacuum port, sight glass lamp,sight glass port with scraper, spice funnel,CIP cleaning, Air respirator

Oil-water pot

The water phase tank and oil phase tank ofthe pre-treatment system preheat anddisperse the raw materials, then transferthem to the main tank, and starthomogeneous mixing to emulsify the

materials

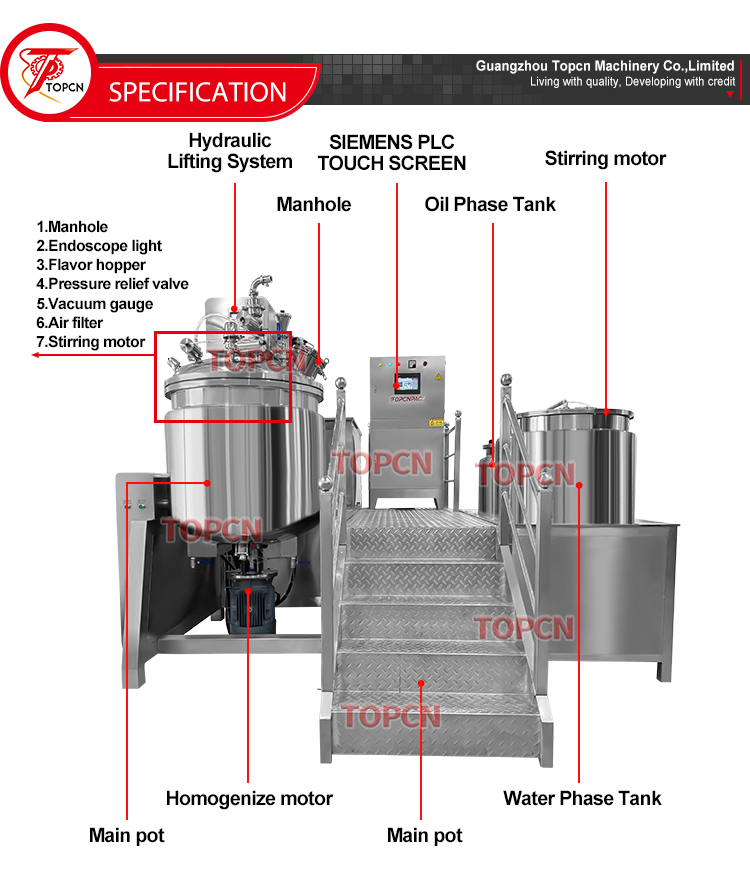

Mixing paddle

Variable frequency speed regulation is0-62r/min, so that different materials can bemixed evenly. The shape of the mixing paddlewill be designed according to your materials

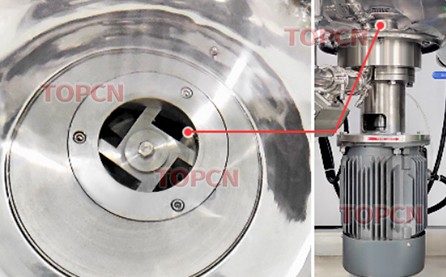

Homogenizer

Frequency conversion speed regulation0-3200r/min,homogeneous shearinghead high-speed shearing materials, sothat the materials are completely brokenand mixed!

Console

The control box includes settings such ashomogeneous shearing, frequencyconversion speed regulation mixing.working timing, vacuum extraction,interlayer heating, etc.

Service

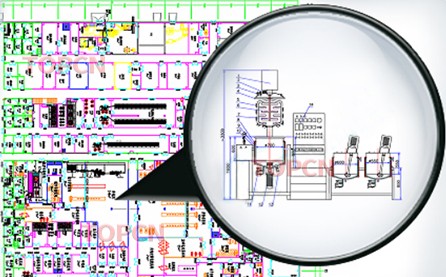

We will design drawings according to yourrequirements and provide one-stop solutions.