Automatic Ex Explosion Proof White Spirit Acetone Thinner Coatings Solvent Chemical Liquid Filling Machine

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

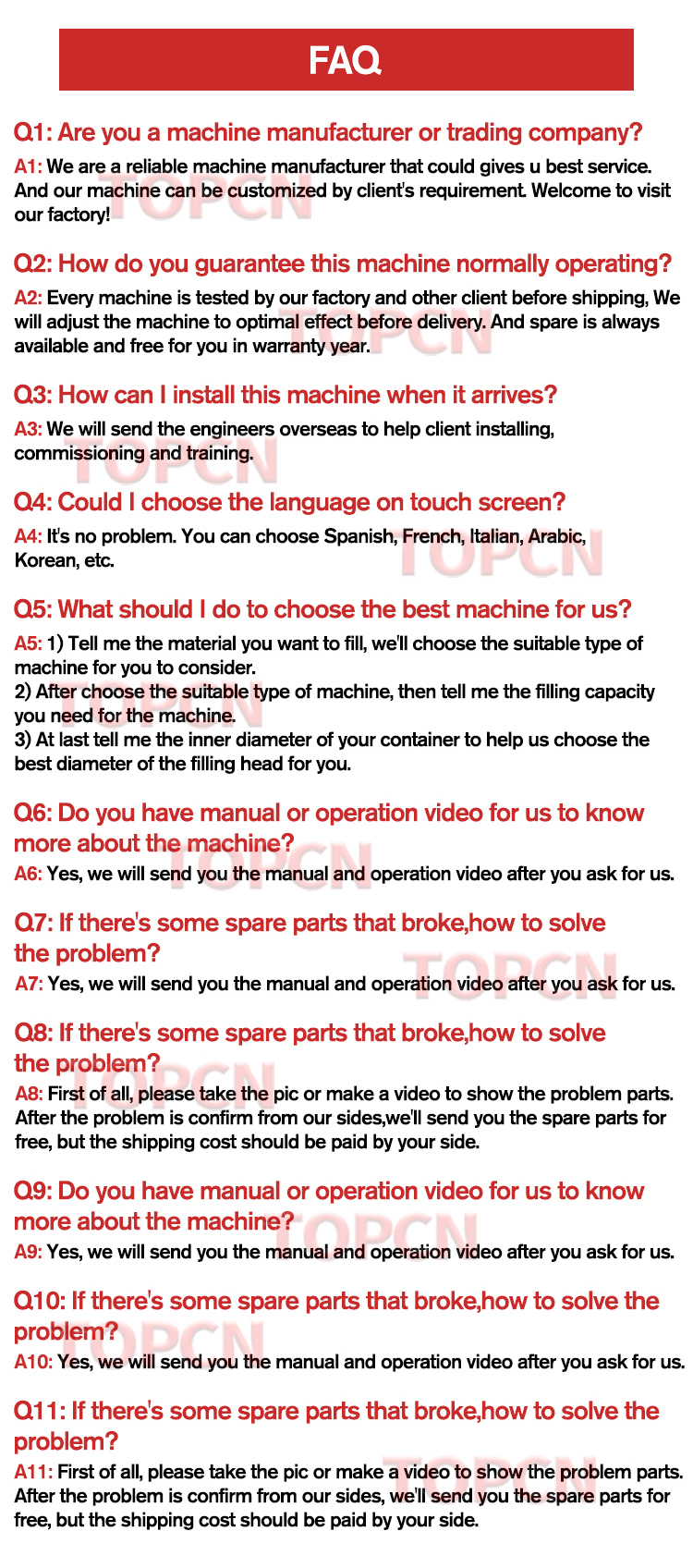

- FAQ

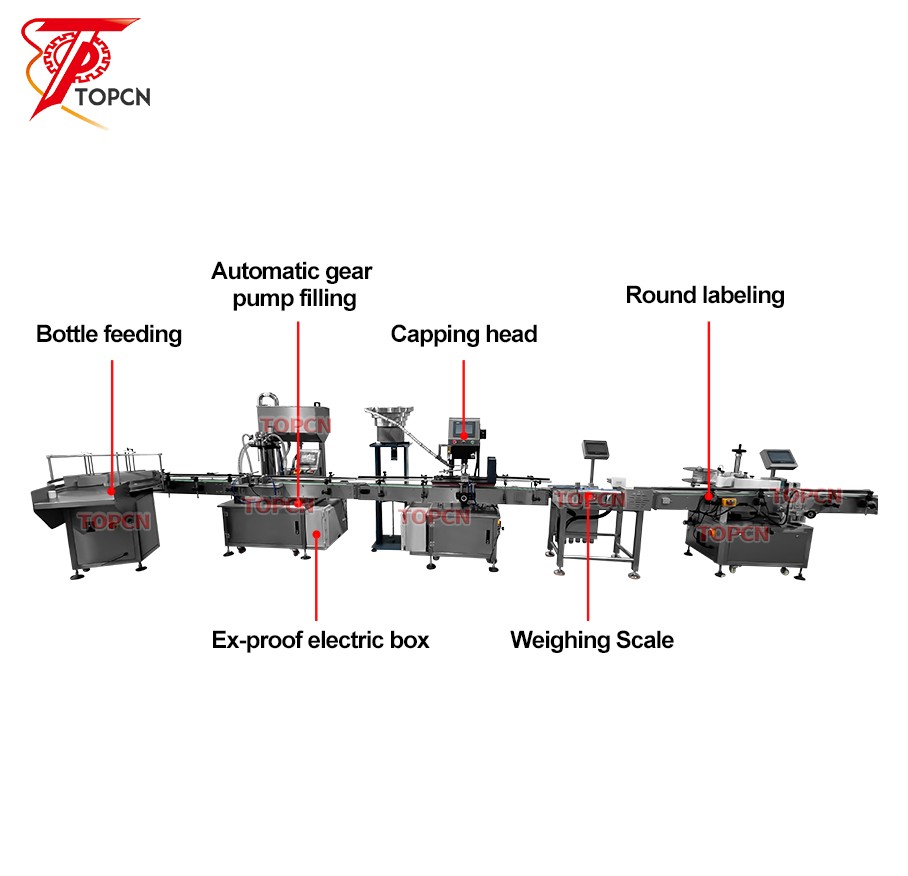

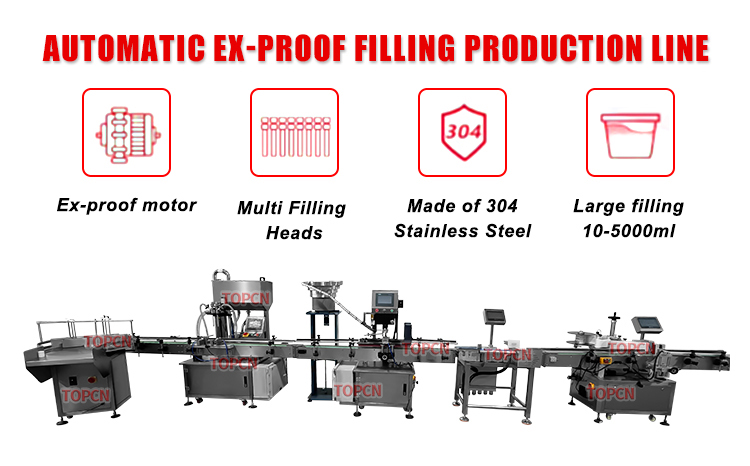

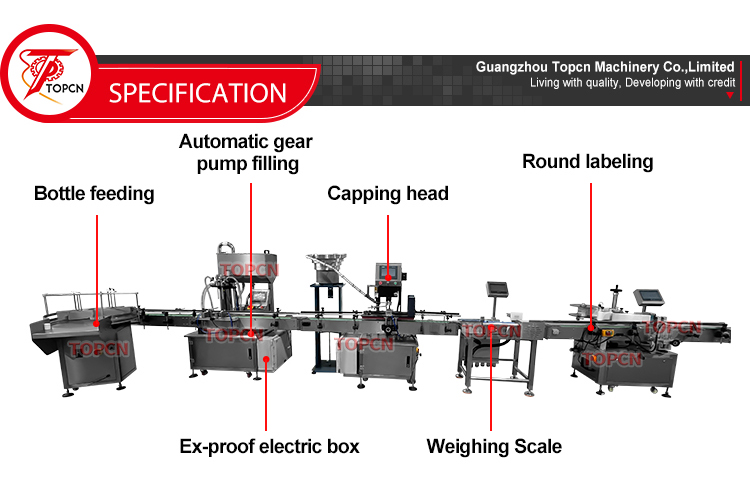

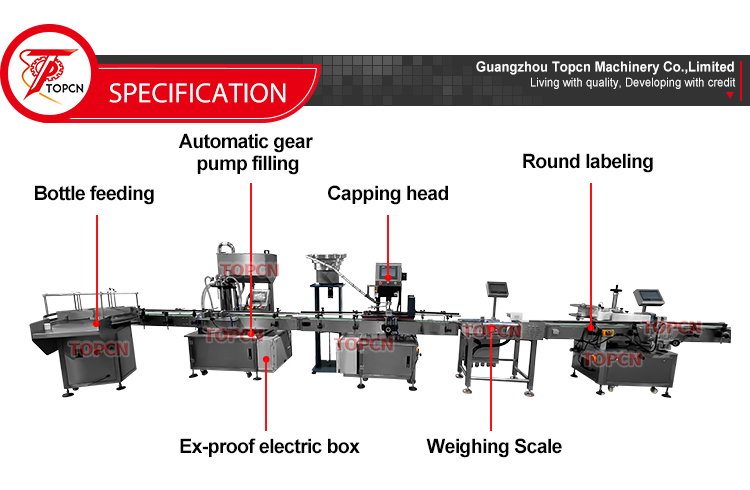

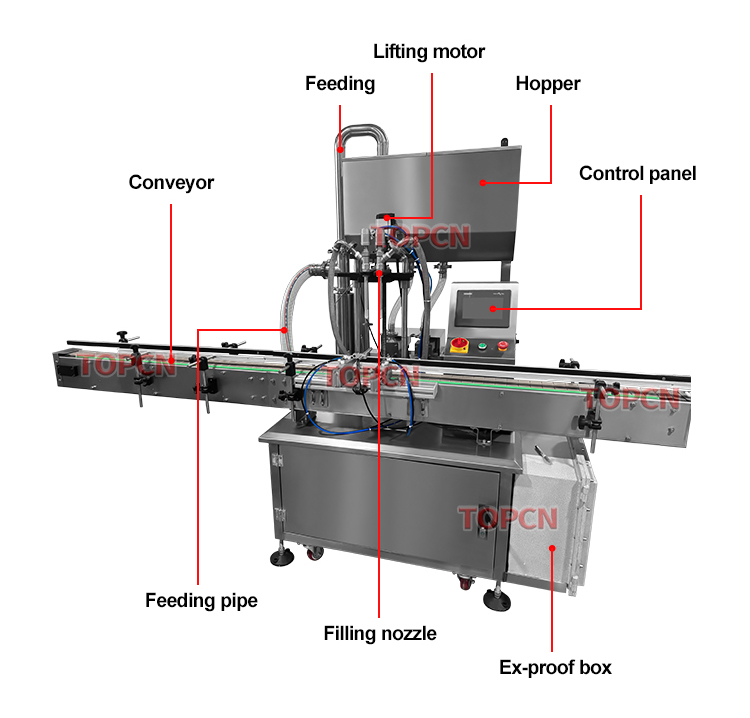

The explosion-proof gear pump production line is designed for handling alcohol-based liquids or pastes such as purifying agents, alcohol, and hand sanitizer gels. These materials are highly flammable, posing significant fire and explosion risks during production, filling, transportation, and storage. Therefore, specialized equipment that meets explosion-proof standards is essential to ensure safety and uninterrupted production.

In the manufacturing of alcohol-based disinfectants like hand sanitizers, medical alcohol, and disinfectant gels, gear pumps serve as critical conveying and metering devices. They are commonly used to move raw materials or finished products between storage tanks, mixers, filling machines, and packaging lines. Because alcohol is highly volatile and has a low flash point, it can easily ignite when its vapor concentration in the air reaches explosive levels. As a result, gear pumps and their associated production lines must be equipped with explosion-proof features

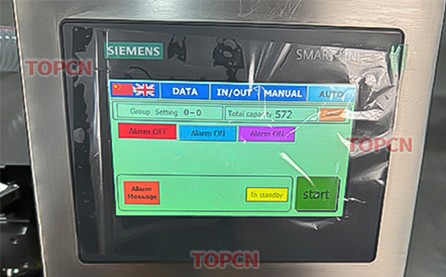

High quality touch screen

High quality PLC ,filling volume, filling speed is adjustable by the touch screen interface,different kinds of operation language can be customized as needed.

Gear pump

Gear pump type filling machine, suitable for viscosity products, such as cosmetic cream, paste, mayonnaise, dressing, chocolate sauce,glue etc.

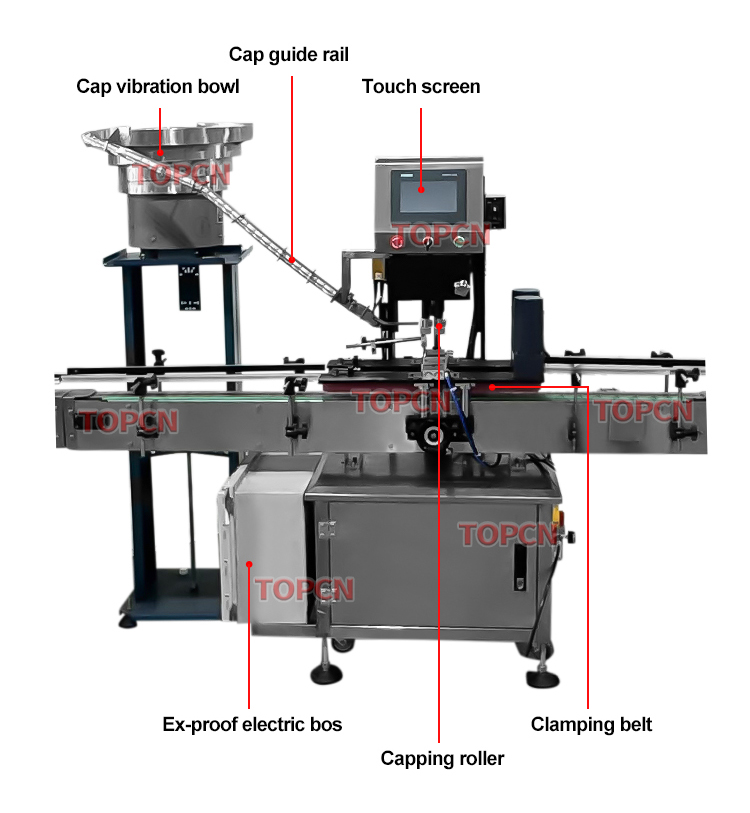

Explosion-proof control box adopt special protective measures in structural design and material selection, which can effectively prevent explosions caused by electric sparks, high temperatures or mechanical friction generated during motor operation, thus ensuring the safety of the working environment and personnel.

Anti-proof filling nozzle

With pneumatic anti-proof filling nozzles, which size according to your product and filling range.

Weighing Scale to check weight of various products, over or less weight will be rejected out, qualify bags will be passed to next equipment.

Product Name | Bottle feeding turntable | ||

Model | TP-LP800 | TP-LP1000 | TP-LP-1200 |

Turntable Diameter | 800mm | 1000mm | 1200mm |

Suitable Bottle Diameter | 20-100mm | ||

Suitable Bottle Height | 30-120mm | ||

Working Speed | 40-60 bottles/min(depends on bottle size) | ||

Motor Power | 0.2KW | ||

Power Supply | 220V/50-60HZ | ||

Net Weight | 109.5kg | 135kg | 165kg |

Machine size | 95*100*110cm | 115*120*110cm | 135*130*110cm |

Package Size | 115*100*132cm | 135*131.5*132cm | 155*150*132cm |

Gross Weight | 155kg | 180kg | 200kg |

Machine model | TPCM-01S |

Voltage | 110/220V 50-60HZ 3KW |

Working speed | 20-40 bottles/min(based on product size) |

Bottle height | About 80-300mm |

Bottle caps diameter | About Φ20-65mm |

Bottle caps height | Customized |

Air pressure | 0.4-0.6MPa |

Machine size | About 3500*2000*2300mm |

Machine weight | About 450kg |

Package size | About 2100*770*1770mm (Main Machine) About 2200*870*1430mm (Cap Elevator) |

Package weight | About 286kg (Main Machine) About 245kg (Cap Elevator) |

Product Name | Automatic capping machine with cap feeder |

Power | 2kw |

Voltage | 220v/110v(Customize) |

Air Source | 0.4MPa-0.6MPa |

Bottle Cap Range | Standard:20mm-68mm; Customize:15mm-70mm;20mm-115mm |

Bottle Size | Bottle height:80mm-300mm; |

Whole Machine Size | L2000mm*W620mm*H1600mm |

Product Weight | About 250kg |

Machine model | TAFM-2GP |

Filling nozzles | 2-12 nozzles |

Power supply | 110/220V 50-60HZ 5KW |

Filling pump | Gear Pump |

Filling range | 100-3000ml |

Bottle size | H=80-180mm W=15-120mm |

Working speed | About 20-80 bottles/min (2 heads) |

Filling accuracy | About ±0.5% |

Air pressure | About 0.5-0.8MPa |

Machine size | About 2900*1400*1980mm(L*W*H) |

Machine weight | About 390kg |

Labeling Precision | ±1mm (excluding product and label error); |

Power Supply | AC220V 50/60Hz 700W |

Conveyor Speed | 5~25 meters/minute; |

Labeling Speed | 10~35pcs/min(Related to product, label size); |

Sticker Out-Come Speed | Stepping Motor: 5~19 meters/minute |

Servo Motor: 5~25 meters/minute | |

Application Bottle Size | External diameter: Φ25-100mm; |

Height: 25mm~300mm; | |

Applicable label size | Label Length: 20mm~290mm; |

Label Width(body paper width): 20mm~120mm; 180mm (option) | |

Inner dia. of paper roll | Φ76mm |

External dia. of paper roll | Max. Φ300mm |

Size (LXWXH) | 2000mm×1150mm×1600mm |

Weight | 185kgs |

Weighing range | 1000g | |

Weighing accuracy | ±0.3g-±1g | |

Display resolution | 0.1g | |

Conveyor speed | 30-100m/min | |

Sorting speed | 160pieces/min | |

Belt height | 700mm±30mm | |

Infeed part | 400(L)*210(W)mm | |

Weighing part | 400(L)*210(W)mm | |

Rejection part | 700(L)*210(W)mm |