Ce Automatic Garlic Chilli Sauce Liquid Tomato Paste Filling And Sealing Capping Machine Production Line For Glass Bottles

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

Voltage | AC220V±10% |

Power | ≤3.6 KW |

vacuum | ≤-0.09MPa(adjustable) |

Air consumption | 1 cubic meters per hour |

Work pressure | 0.8~1.3MPa |

Capacity | 1600-2000BPH |

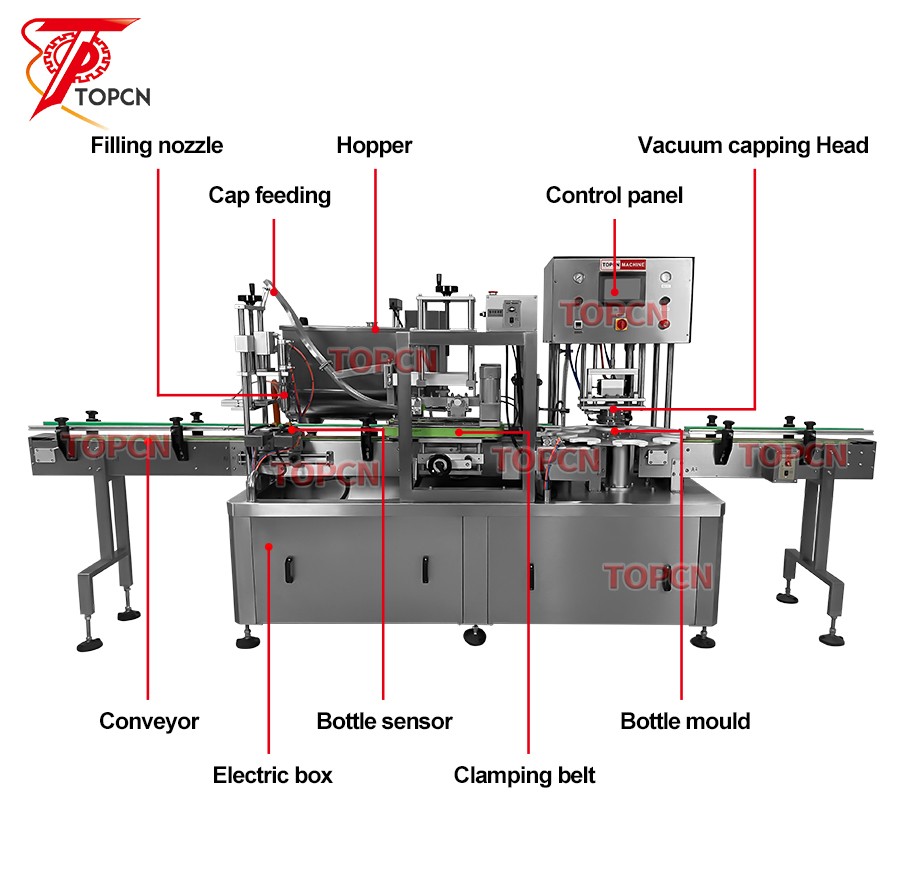

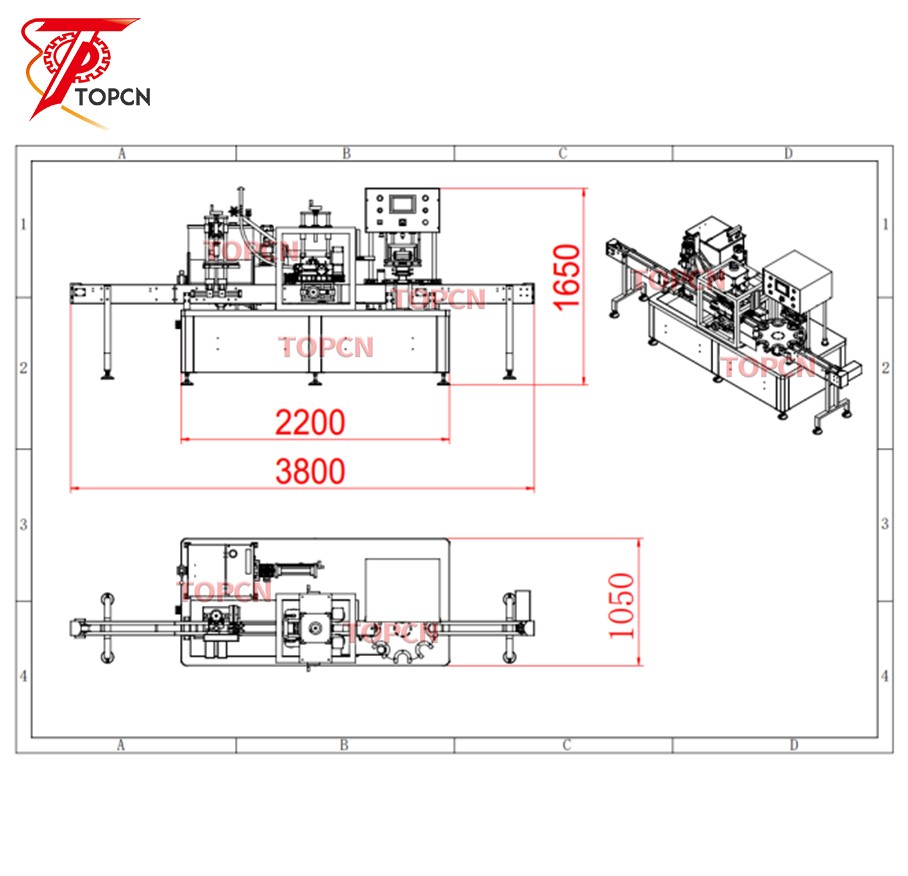

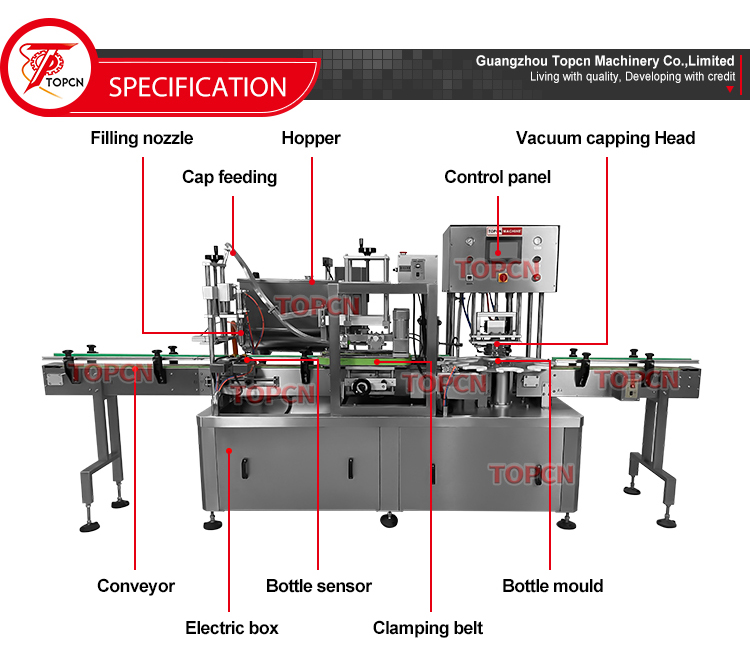

Machine size | 380*105*165cm |

N.W | 650KG |

bottle mouth dia | 30-120mm |

Bottle dia | 30-220mm |

Bottle height | 40-210mm |

Bottle shape | round or other shape |

Filling volume | 50-500g |

Sealing method | Airbag seal |

Packaging type | bottles/jars |

Package material | Plastic/Glass |

Filling products | chili,Douban,sesame paste honey,sauce,and other granular material |

Application | It is applied in food industry |

degree of automation | Automatic |

N.W(kg) | 150 |

Filling precision(%) | ±1% |

Voltage | 220V other voltages can be customized |

Type of power | Piston pump or lobe pump |

L*W*H | 200*100*160cm |

Core components | Pneumatic system |

Filling nozzles | customizable (2.4, 6, etc.) |

Filling volume(xx-xxml) | 10-150g 25-250g,50-500g |

Speed(BPH) | 1 head:15-20bpm 2 head :20-25bpm |

Powder(KW) | 2.5Kw |

Item NO | TAFM-PM |

SI | Name | Brand |

1 | CPU | Mitsubishi |

2 | Touch screen | Mitsubishi |

3 | Sensor | SICK |

4 | Switch | Omron |

5 | Pneumatic | SDAD |

6 | Piston | SDAD |

7 | Valve | Airtac |

8 | Relay | Airtac |

9 | Power switch | Delta |

10 | Small relay | Schneider |

11 | Electric button | Schneider |

12 | Vacuum pump | Jiangsu |

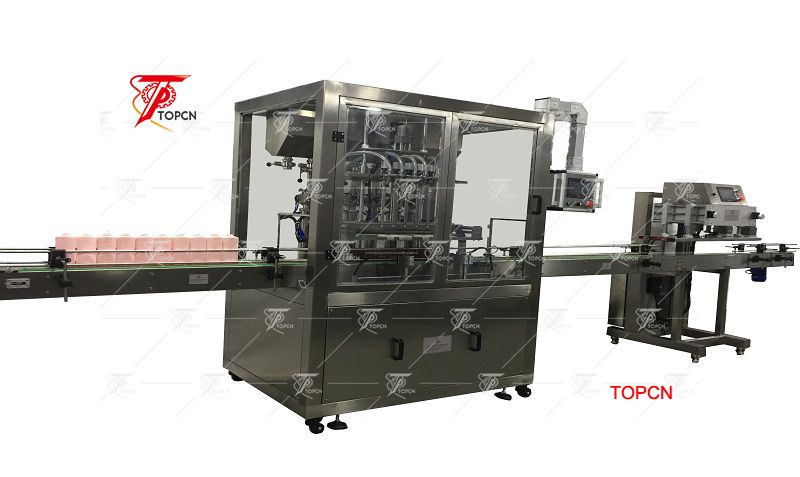

- Cosmetic Lotion Filling Machine

- Automatic Shampoo Bottle Filling Capping Machine Labeling Machine Made In China

- Automatic thai herbal balm cosmetic cream hot wax grease filling machine with mixing

- Beer glass bottle semi automatic tomato sauce filling machine with capping machine

- Hot sale semi automatic mixing and heating lipstick bottle filler paste filling machine for cosmetics cream

- Factory price automatic chubby gorilla bottle eliquid filling machine for 30-120ml bottle

- Manual lipstick mixing lip balm filling machine lipstick filling mold machine for mascara

- Automatic Desktop Single Diving Head 2000BPH Automatic Servo Gear Pump Filling Machine Manufacturing Plant