Automatic Industries Chemical Milk Coffee Dry Powder Auger Spics Tea Powder Bottle Filling Capping Labeling Machine

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

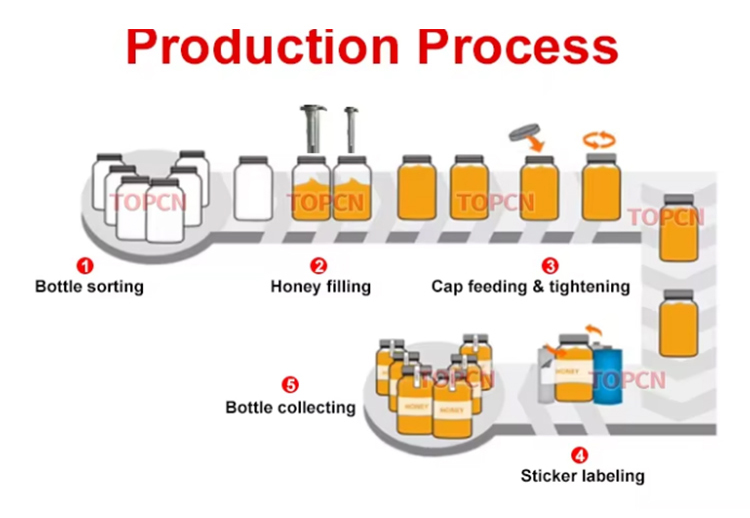

Application

Suitable for food, medicine, biology, chemical industry and so on.Such as dry powder,coffee powder, veterinary drugs, powder granular additives, sugar, glucose, monosodium glutamate, solid drinks, solid medicine, carbon powder, powder, pesticides, dyes, flavors, etc.

Features

1.Made of stainless steel 304, meet GMP standard

2.Servo control auger, more stable and accuracy -Step motor can be economical customized

3.PLC+ Touch screen control, English version interface

4.Electric scale or load cell connect with touch screen for weight feedback, machine can be used by weight or by volume according the user need

5.Same material same screw ,once 1 spec parameter item preset , just change the target weight on work page then inner item like the fast filling weight , slow filling weight and mini weight value will be change automatically

6.Changing the auger attachment, it fits for lots of material ranging from fine-powder to granule.

7.Top Hopper equipped with level sensor to control the feeding machine work automatically

8.Foot Pedal control filling

9.50L Hopper can be half open and it more easy for screw change or inner wall cleaning

10.Stand pole of filler is in round shape. All parts like the electric cabinet ,touch screen box ,bag clamber or scale frame etc fixed on it easily by metal clamber .

11.Material entrance and dust exit on both side of auger filler .it can be changeable so feeder can be placed from different side according user workshop situation.

12.Insider mixing blade can be adjustable by bolts to match different size screw to assure the accuracy when packing

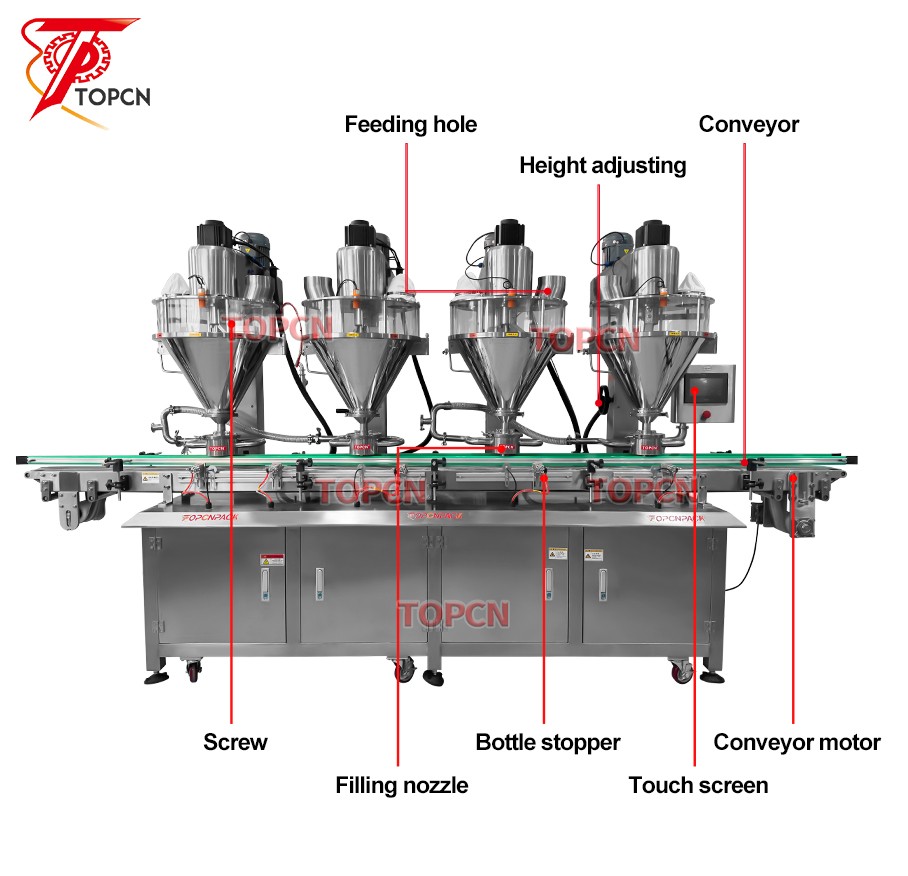

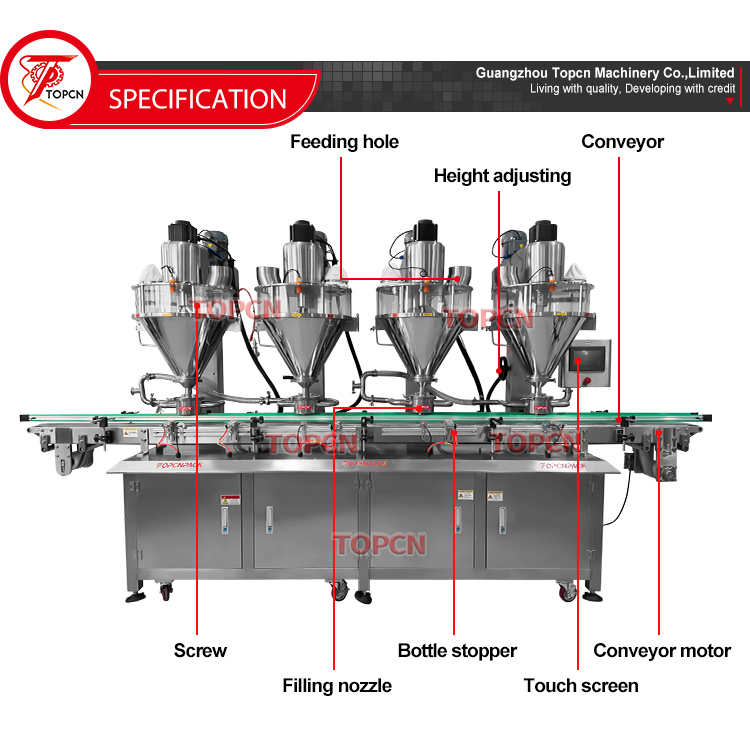

4 Filling Heads

Four filling heads can operate simultaneously to enable multi-channel parallel filling, while each head can be independently controlled to ensure precise dosage and operational flexibility.

Screws and Mixers

Transparent viewing window, clean and see the material capacity of the hopper. It can be used for filling 10-5000 gram powder by replacing the screw.

Control Panel

Touch screen control panel, easy to adjust various filling parameters. The PLC control system makes the machine work more stable.

Good quality and fine polished auger screw

Wide filling range,the filling volume and speed all can be adjustable.

Suit for powder to small particles and other materials

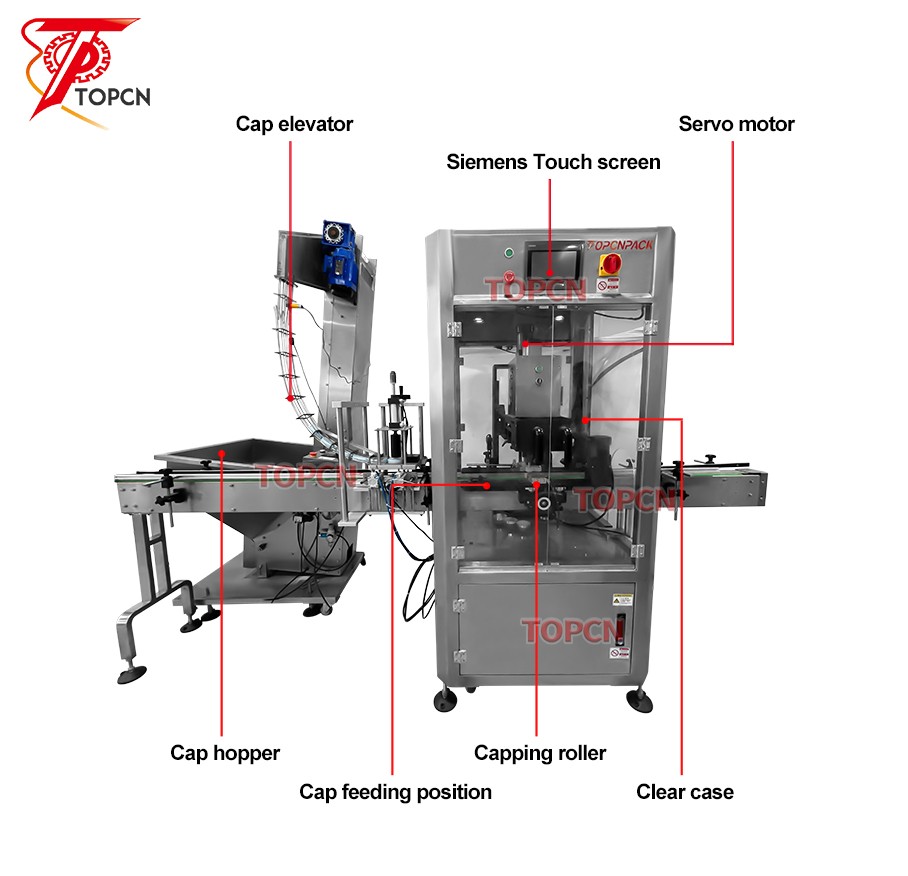

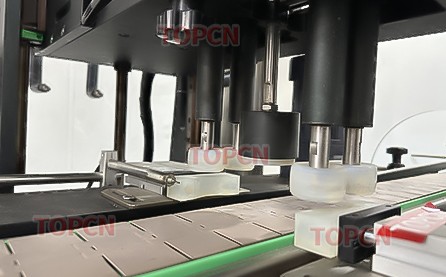

Press Capping

With chain rail to press bottle caps,it can press multiple bottles at the same time, greatly improving efficiency.It can be customized according to your products.

4 Wheel Capping Head

fits multiple cap types (spray, pump, dropper) and securely tightens them with consistent pressure, delivering unmatched efficiency in bottling operations

Main Features

1) The whole machine is mainly made of stainless steel 304.

2) Hanging type hopper, easy to remove and wash without tools.

3) Servo motor control, electronics switch control, packaging containers unlimited (bags, cans, bottles can be).

4) Can be equipped with feeding machine automatically control material level, more convenient to use, at the same time reduce labor costs, improve production efficiency.

SPECIFICATIONS AUTOMATIC POWDER FILLING MACHINE | |

Filling Head | 4 |

Filling method | Screw metering (or electronic weighing) |

Auger volume | 30/50L(can be customized) |

Feeder volume | 100L(can be customized) |

Machine material | SS 304 |

Filling volume | 1-1000g(can be customized) |

Filling accuracy | ±1%(different volume and material,accuracy will be little different) |

Filling speed | 20-60 BPM |

Weight | 1750KG |

Dimension | 320*95*199cm |

Package size | 383*110*215cm |

G.W | 2000Kg |

Name | Press capping +Cap feeding+Automatic capping machine |

Voltage | 110/220V 50-60HZ 3KW |

Working speed | 20-40 bottles/min(based on product size) |

Bottle height | About 80-300mm |

Bottle caps diameter | About Φ30-90mm |

Bottle caps height | Customized |

Air pressure | 0.4-0.6MPa |

Machine size(L*W*H) | About 3500-2000*2300mm(L*W*H) |

Machine weight | About 450kg |

Package size | About 2100*770*1770mm (Main Machine) |

Package weight | About 286kg (Main Machine) |

Product Name | Bottle feeding turntable | ||

Model | TP-LP800 | TP-LP1000 | TP-LP-1200 |

Turntable Diameter | 800mm | 1000mm | 1200mm |

Suitable Bottle Diameter | 20-100mm | ||

Suitable Bottle Height | 30-120mm | ||

Working Speed | 40-60 bottles/min(depends on bottle size) | ||

Motor Power | 0.2KW | ||

Power Supply | 220V/50-60HZ | ||

Net Weight | 109.5kg | 135kg | 165kg |

Machine size | 95*100*110cm | 115*120*110cm | 135*130*110cm |

Package Size | 115*100*132cm | 135*131.5*132cm | 155*150*132cm |

Gross Weight | 155kg | 180kg | 200kg |

Product Name | Bottle collection turntable | ||

Model | TP-SP800 | TP-SP1000 | TP-SP-1200 |

Turntable Diameter | 800mm | 1000mm | 1200mm |

Suitable Bottle Diameter | 20-100mm | ||

Suitable Bottle Height | 30-120mm | ||

Working Speed | 40-60 bottles/min(depends on bottle size) | ||

Motor Power | 0.2KW | ||

Power Supply | 220V/50-60HZ | ||

Net Weight | 109.5kg | 135kg | 165kg |

Machine size | 90*90*110cm | 115*115*110cm | 130*130*110cm |

Package Size | 110*110*130cm | 125*125*130cm | 140*140*130cm |

Gross Weight | 95kg | 120kg | 135kg |

- Automatic Chocolate BBQ Tomato Paste Chilli Sauce Ghee Jar Sauce Cooking Filling and Labeing Line Machine

- Automatic Two Head Servo Rotor Pump Oil Cream Shampoo Laundry Detergent Honey Paste Linear Filling Capping Machine

- Automatic Viscous Liquid Pail Big Barrel Drum Bucket Cooking Oil Detergent Shower Gel Shampoo Filling Machine Line

- Customized Filling Nozzle High Speed Tracking Filling Machine Round Bottle Filling Capping and Labeling Line

- High Quality Full Automatic Capsule Vitamin C Milk Tablet Counting and Packing Machine Line

- 6 Heads Automatic Benchtop Liquid Oil Peristaltic Pump Belt Conveyor Beverage Juice Syrup Filling Capping Machine

- Full Automatic Inline Perfume Glass Oil Bottle Filling Equipment Caps Pressing Crimping and Labeling Machine Line

- 4 Heads Magnetic Pump Chemical Oil Milk Beverage cosmetic Cream Jam Filling Capping and Labeling Machine